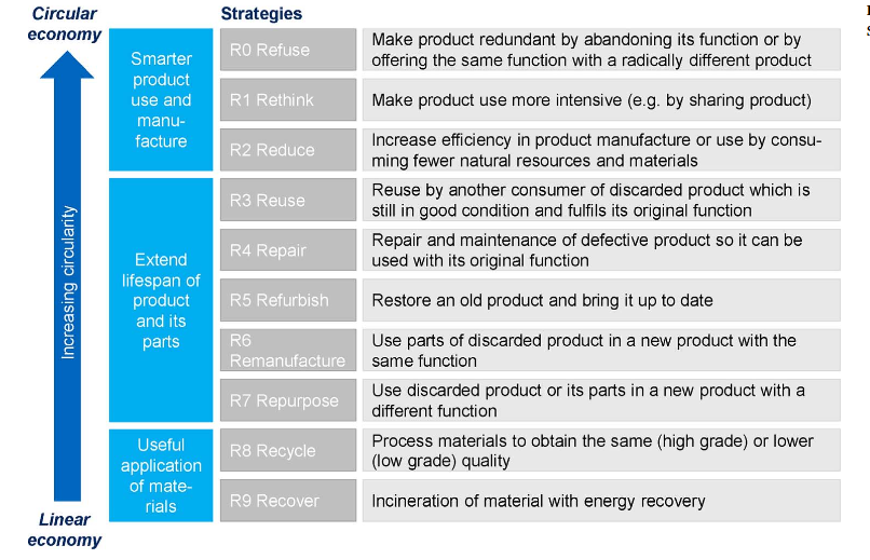

The model suggested by the PBL Netherlands Environmental Assessment Agency (2017) is presented in the figure below. The model which defines ten strategies for circularity that can be used to build a successful circular product and material flows across the EU. Each strategy is based on making use of different business models, infrastructures, relationships with different stakeholders, and potentially also policies.

Smarter product use and manufacture

- R0 Refuse: Refuse the use of raw materials, design production processes to avoid waste. On consumers’ side it is about choosing to buy and use less, reject packaging waste.

- R1 Rethink: Make product use more intensive (e.g. through sharing products, or by putting multi-functional products on the market). This strategy engages producers in a process of re-designing or ‘rethinking’ their products, in order to minimise the environmental footprint and reduce the amount of resources used in the production process.

- Product as a service;

- Sharing of assets;

- Industrial symbiosis;

- Performance-based input sharing

- R2 Reduce: Increase efficiency in product design or manufacturing by using fewer natural resources and materials as inputs. The strategy of reducing the products’ ecological footprint by increasing resource efficiency can involve different levels of ambition in the transformation of the products.

- Deploying different processes or technologies that use less energy, water, raw materials, etc.,

- Re-organising logistical chains and suppliers (e.g. buying from more local suppliers).

Strategies extending the lifespan of products and its parts

- R3 Reuse of discarded products by another consumer. This strategy is key to supporting material flows in the economy, and advocates the designing of products with longer lifespans, more robust composition, and which are easily repaired.

- R4 Repair and maintenance of a defective product so it can be used for its original purpose, and

- R5 Refurbish to bring an old product up to date are further strategies that can be used along the same thinking lines of prolonging the lifespan of products.

- R6 Remanufacturing or using parts of a discarded product in new products with the same functions.

- R7 Repurposing or using parts of a discarded product in a new product with different functions.

Useful application of materials

- R8 Recycling: Treating waste to generate secondary raw materials as inputs for processed materials.

- R9 Recover: Incineration of materials with energy recovery. Incineration of materials is a waste-treatment technology, based on the combustion of waste that is used for energy recovery. It is one of the last waste management resorts used before landfilling

For more information consult